This contribution addresses

and reviews current and progressing CRM supply trends and needs, potential mineral

resources targets invented, and related key value chain developments with the

EU industry in focus, by mainly looking for answers to the following questions.

- Why and how a European CRM list?

- What is the current state and what needs to be done in

the fields of CRM Economic Geology and related value chains?

- Bottlenecks that today make CRM industry perspective

and future difficult to be predicted and any foresight studies undertaken

becoming uncertain; the example of cobalt

- Which are then the risks, impacts and consequences

that might be emerged and which could be the solutions?

Current CRM

list

Critical

Raw Materials are both of high economic importance for the EU and vulnerable to supply

disruption. These limitations and conditions became the major elements of the

methodology applied to provide the 2017 criticality assessment, with the 26 raw

materials shown below, excluding lithium.

European mineral raw

material challenges

The mining sector and

the mineral processing sector are vital to securing the supply of metals

extracted in a sustainable manner to be used in high-tech value chains and to

address challenges considering that,

- The mineral value chain spans from geological exploration, mining and

processing to the recycling of metals.

- There is a strong

environmental commitment both during operation, as well as for the reclamation

of land used for mining, embedded in value chain.

- The transition to a low-carbon, fossil-free sustainable Europe and the

green economy is a prime societal challenge.

- The electric infrastructure as well as energy storage systems, renewable

energy power plants and vehicles have a tight implementation agenda.

- Fossil-free

aggregate production to build new transport infrastructure as well as new green

buildings has a central role

Strategic

mineral-based value chains for the EU

The EU, and apparently

the rest of the world, is challenging a growing

demand for mineral raw materials stemming mainly from the emerging

digital revolution, the innovation to e-mobility and artificial intelligence

technologies, and the transition towards a low-carbon and low-waste future.

This development is triggering and enabling reshaped or new value chains of mineral raw materials industries from the

upstream to the downstream, e.g. from exploration, mining, processing

and products along the value chain to end-use manufacturing. The intensity on

the economy and society, in securing the increasing resources potential and

supply needed, will continue remaining notably high, particularly in the case of critical raw materials which

by almost 60% are related to high-growth enterprising.

The six identified strategic mineral-based value chains require sustainable

supply of certain raw materials, beyond only the critical ones.

- Renewable energy –Wind & PV value chain: Al, Cu, Pb, Nd, Pr, Dy,

B, Mn, Ni, Cr, Fe, Mo, Nb, Ag, Zn, Ga, Se, Te, Cd, In, Si,

Sn

- Grids value chain: Cu, Al, Ni, Fe, Si

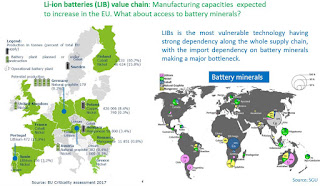

- Li-ion batteries (LIB) value chain*: Ni, Co, Cu, Li, Al, Mn, V, C-graphite

- Electric vehicles (EVs) value chain*: Ni, Co, Cu, Li, Al, Mn, C-graphite, Fe, Cr, Mo, V, Si,

Mg, B, Nd, Pr, Dy

- Robotics value chain: Fe, Al, Cr, Co, Mo,

Si, C-graphite, Ti, Ni, Mg, V, Cu, Pb, Ag, Sn, Sb, Bi, Au, Mn, Zn, REE, Li

- Defense value chain: Al, Cu, Pb, Nb, W, Ba,

Ga, Li, Rh, V, Be, Ge, Mg, Ta, Zn, Cd, Hf, Mn, Zr, Cr, In,

Mo, Sn, Co, Fe, Ni, Ti, Dy, Nd, Pr, Sm, Yb, Au, Pt, Ag, B,

Se

Considering the value chains and related raw materials it is found out

that,

- China delivers around half of the raw materials required for all six

strategic value chains.

- China keeps its leading position across all domains (extraction,

processing, refining) of CRM value chains.

- Europe is less dependent further down the industrial value chains.

- Europe is vulnerable to supply of RM for all mentioned value chain

technologies/sectors.

- LIB is the most vulnerable technology: strong dependency along the whole

supply chain.

- Higher resilience of Europe downstream the supply chain, for example

processed materials.

- Best case for Grids, as Europe is self-sufficient on the raw materials

needed.

- The renewable energy, Li-batteries and electric vehicles value chains are

closely related and interlinked, having a crucial role in implementing the

Paris declaration and the SDGs, as well as to address a low-carbon and green

economy future.

Electrification

and artificial intelligence

It is evident

that electrification and artificial intelligence make top priorities of EU’s

industrial strategy and related sustainable development, with respect to mainly

SDGs and climate change agenda. Raw materials and advanced materials are the

key enablers for the transition in the energy and mobility sectors. Since

electrification is the basis for the transition from brown to green economy to

happen, there will be enormous amounts of electricity needed to be produced, of

course, from renewable sources. Having all this in mind and in relation to all

outlooks showing a strongly growing demand for energy and increasing

requirements for responsible mining, two more value chains seem to be strategic

targets,

·

Renewable energy –Wind & Photovoltaics (PV) value chain, and

· Robotics value chain

The example

of cobalt

Although any kind of forecasting is uncertain all scenarios indicate that

cobalt demand for Li-battery manufacturing will exceed the supply until 2030,

given the total number of more than 110 million electric cars expected to be

produced by then. This anticipates also an exponential growth in the demand for

other battery raw materials like nickel, aluminium, copper, graphite, lithium

and manganese minerals. Under average conditions around 64.000 tonnes of

additional cobalt will be needed to cover global demand in 2030. By then

internal EU supply can meet only 15% of European demand in the electric vehicle

sector, this way leading to a growing gap between internal supply and demand. In

the case of graphite, the demand will grow from 5.700 tonnes today to 157.400

tonnes by 2030. It is obvious that

mineral raw materials availability and stable supply is strongly influencing

and determining the large-scale deployment of EVs. Of course, cobalt

availability may be available but most probably at the expense of increased

prices for battery manufacturers and continued dependence on unethical supplies

from Democratic Republic of Congo (DRC). To avoid it future mobility would have

to rely on cobalt extracted within the EU by opening of new mines and

recovering it through recycling.

Economic

geology of European CRM and battery minerals

The problem

seems not to be the CRM Geology approach at EU level although this will also

need to take some time developing the Economic Geology models and achieve

credible resource potential estimates and exploitation schemes.

Securing raw

materials supply sustainability, further surveys and exploration need to be

conducted on two challenging resource potential targets indigenous to the EU.

PRIMARY RESOURCES

The main

challenges for sustainable supply of primary CRM in Europe are:

- Development of

innovative technologies addressing exploration of CRM to discover new potential

deposits on land and off shore.

- Development of

new primary CRM production in Europe will decrease import dependence and make

sure that exploitation takes place under sustainable conditions. This includes

the necessity for exploration of deep-seated deposits in brownfield areas

across the EU where potential CRM resources may occur in genetic associations

with common industrial and other high-tech metals.

- Adapting

technology, economical constraints and mind-set to allow for the exploitation

of smaller and lower-grade deposits.

- Mining

technologies adapted to the treatment of primary mineral resources with

increasing complexity and decreasing grade.

- To refine low

grade ores and materials containing CRM while reducing energy consumption and

environmental impact.

- The need to

develop methods for extracting all valuable metals from currently-mined ores

and recycled materials, including minor elements that are commonly now

rejected.

- Development of the

technologies adjusted to the properties of the processed CRMs to increase

- extraction efficiency and metal recoveries

MINERAL-BASED

WASTES

The main

challenges related to supply of secondary CRM from mineral-based wastes, e.g.

mining waste,

processing tailings, in Europe are:

- Insufficient

information about CRM compositions and volume characteristics in the mineral

resources from primary ore deposits.

- Insufficient

information about CRM compositions and volumes in mineral based wastes like for

example mining waste such as dumps and tailings.

- Insufficient

knowledge about mineralogical and geochemical behavior of CRM during mining and

processing using physical and chemical methods.

- Insufficient

information about the mineral-based character of residues, and their physical

and chemical properties.

- Insufficient information

about overall availability and resource potential of historic mining sites.

- Insufficient

information about historical smelter locations and metallurgical wastes.

- High losses of

CRM during pre-processing, impurities degrading product/residue quality.

- Lack of

systematic identification/mapping of mining waste sites for future CRM

extraction.

- Lack of a unified

system for resource classification of CRM (e.g. UNECE/UNCF system) in various types of

mining waste.

- Lack of specific

methods of extracting metals and other valuable products from secondary, often

heterogeneous sources.

- Overall lack of a

full inventory and range of metals to anticipate future demand.

Potential

challenges, opportunities, risks and barriers

- The problem seems

not to be the CRM Geology approach at EU level although this will also need to

take some time developing the Economic Geology models and achieve credible

resource potential estimates and exploitation schemes.

- Recycling and

substitution are not now reliable CRM resource providers. In a way, recycling is a

target but not a solution

- Dubious, lame,

limping and failing progress of CRM value chains, and lack of balance between

upstream-downstream efforts e.g. electric vehicles boom when energy transition

and battery mineral resources are yet not secured.

- Car-makers are keener

to increase their production and sales in EVs and forget to pay proper

attention to issues concerning the CRM supply needed.

- Increased

regulation vs Regulatory risk: Need for innovative policy instruments that are

beneficial to all parties and work constructive rather than contradictory.

- Considering the

long period of time (from exploration to mining takes about 15 years) needed

for the CRM value chains to be fully operational, the technologies addressing

the implementation plan of climate change goals might not always readily

available due to lack of the mineral resources needed.

- Determined

authorisation, decision-making and permitting procedure for a sustainable CRM EU-based

industry is necessary if stakeholders are really interested and committed to

develop and use climate-smart technologies, and to make the energy transition

happen.

- The Social

License to Operate concept or principle makes at present an old approach, needs

to be left behind and should be replaced by currently sound societal

challenges, such as the low-carbon and low-waste future.

- Ethics will

have an impact on resource and supply issues related to some raw materials,

such as Co, Nb, Ta.

- Financial uncertainties e.g rising costs, digital effectiveness,

artificial intelligence, energy.

- China will continue controlling and driving

mineral geopolitics in relation to high-tech value chains.

The way

forward

- Raw Materials from European primary and secondary

resources are ideally suitable for establishing a system of responsible

sourcing: raw materials produced in Europe can be taken as a guarantee for high

standards in social, environmental and economic terms.

- Further surveys and exploration need to be conducted

on primary and secondary resource potential targets indigenous to the EU.

- Criticality in the future also needs to include the

issue of “responsible production and consumption” according to the SDG 12 goal.

- Elements and practices related to circular economy,

responsible sourcing and resource efficiency addressed by the new EU industrial

strategy, should be particularly considered

- Major European mineral belts, such as Fennoscandian,

Iberian, Carpathian-Balkan, host highly potential exploration targets

challenging the likelihood for discovery of new resources and feasible mining

prospects.

- Europe’s opportunity to become self-sufficient and

sustainable in mineral raw materials supply from own sources and resources, is

strongly favored by its geological setting and metallogenetic evolution.

- For the EU to secure and maintain a full operational

capability and capacity of the value chains mentioned above access to land is

fundamental, making sure that responsible and innovative land stewardship

throughout the mining life cycle is considered.

- Sustainable land- use related value chains integrates

and maximises the multiple benefits related to economic, social, environmental

and cultural values.

- The value chain approach enhances the steering

capacity for the preparation and implementation of sustainable land-use plans

addressing minerals development.

- Looking for optimisation of future balances between

supply and demand.

Sources,

links and references

- https://ec.europa.eu/jrc/en/publication/eur-scientific-and-technical-research-reports/cobalt-demand-supply-balances-transition-electric-mobility

- http://iapgeoethics.blogspot.com/2019/01/circular-economy-is-about-resource.html

- https://ec.europa.eu/growth/sectors/raw-materials/specific-interest/critical_en

- Alves Dias P., Blagoeva D., Pavel C., Arvanitidis N., 2018: Cobalt: demand-supply balances in the transition to

electric mobility. JRC Science for Policy Report, European Commission.

- Blagoeva D.,

Pavel C., Alves Dias P., 2018: Critical raw materials in strategic value

chains. JRC Petten, Raw Materials Week, 2018.